We would like to hear from you with any feedback about our website or products.

$27,500.00

Cost: $27,500.00 (DLF-220L) / $36,250.00 (DLF-350L)

Volume: Low-medium (highly versatile).

Max. Cut Speed: 24 in/s (600 mm/s) in all directions

Input / Output Max. Roll Diameter: 9.84 in” (250 mm)

Min. Media Width: 4.33″ (110 mm)

Max. Media Width: 8.86″ (225 mm)

Max. Cutting Width: 7.87″ (200 mm) / 13″ (330 mm)

Min. / Max. Label Length: 8.86″ (225 mm)

Min. Slitting Width: 0.39″ (10 mm) / 15″ (381 mm)

Maximum Media Thickness: 10 mil (0.25 mm)

Weight (Estimated): 396 lbs. (180 kg)

Roll Core Size: 3 in” (76 mm)

Warranty: 1-year parts and labor. Usage limitations may apply

The price of the DLF-220L does not include freight.

Contact us for shipping costs.

DLF-220L / DLF-350L Digital Label Finisher

DLF-220L Product Code: 28053

DLF-350L Product Code: 29740

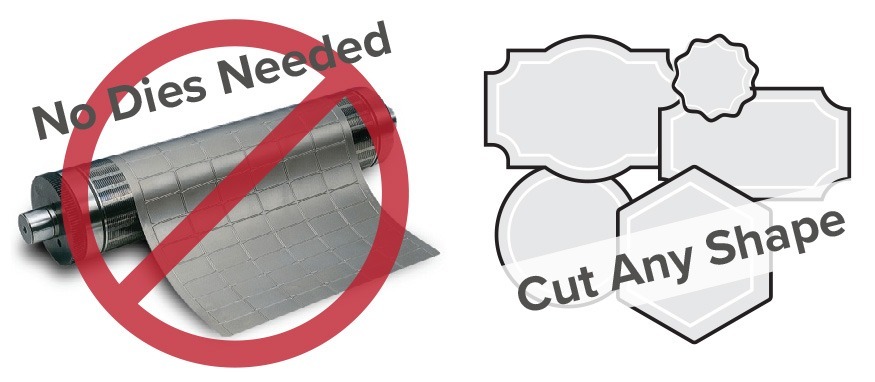

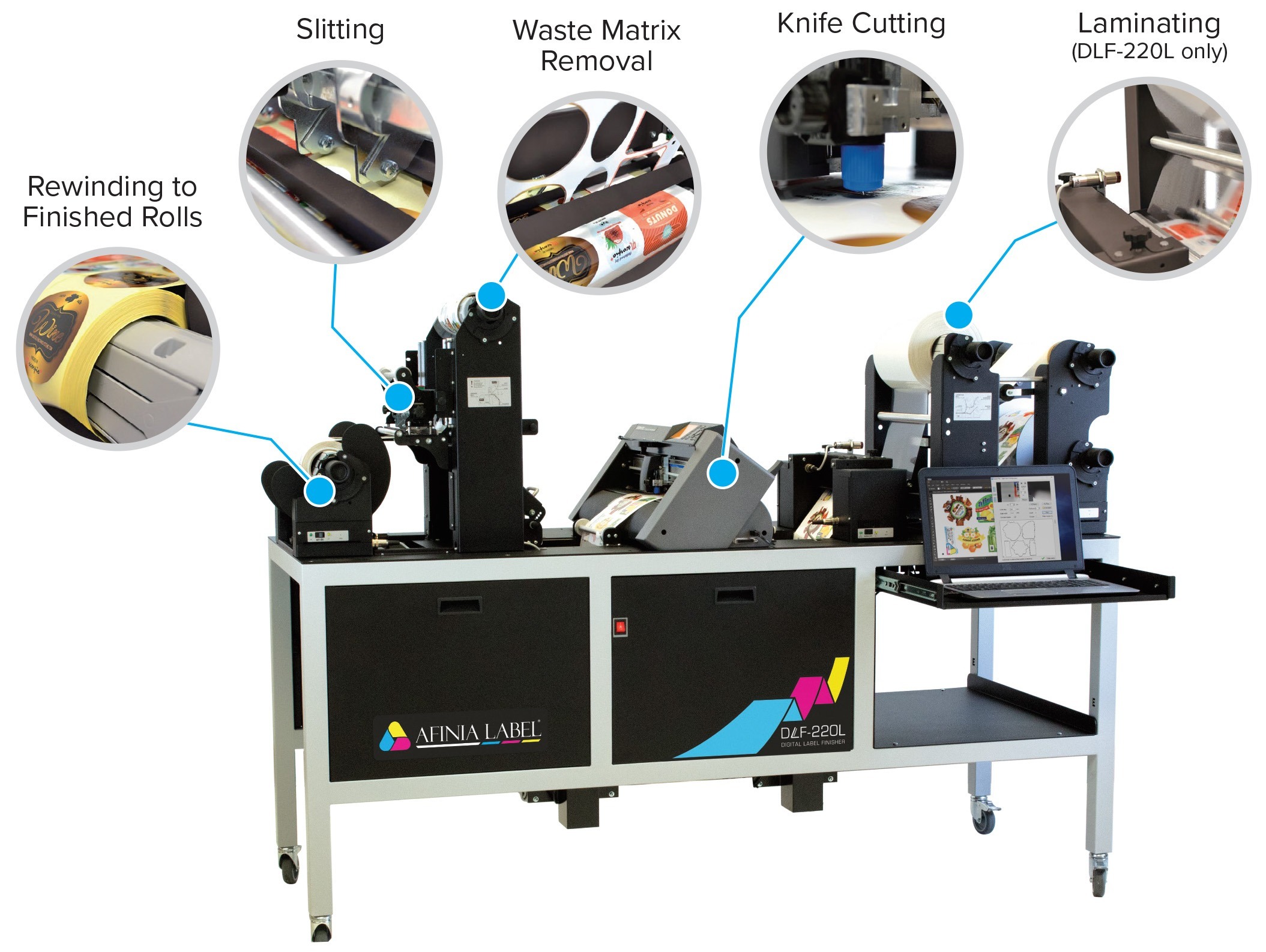

Cut any shape digitally, without the use of dies. Ultra-precise cutting abilities easily produce beautiful full-bleed labels without costly dies. A digital cut file guides the DLF’s plotter as it converts uncut, continuous-printed media into fully finished labels. Afinia’s Digital Label Finishers are systems that unwind, laminate, digitally contour cut, remove waste, slit, and rewind all in one simple process to create professionally finished labels. These solutions are perfect for finishing on-demand, short-run label jobs printed on any digital Afinia Color Label Printer.

Cut any shape digitally, without the use of dies. Ultra-precise cutting abilities easily produce beautiful full-bleed labels without costly dies. A digital cut file guides the DLF’s plotter as it converts uncut, continuous-printed media into fully finished labels. Afinia’s Digital Label Finishers are systems that unwind, laminate, digitally contour cut, remove waste, slit, and rewind all in one simple process to create professionally finished labels. These solutions are perfect for finishing on-demand, short-run label jobs printed on any digital Afinia Color Label Printer.

Afinia DLF-220L / DLF-350L Compact Plotter-Style Label Finishing System.

This full-size finisher is available in two widths (8.6 in/220 mm and 13.75 in/350 mm web widths), with or without lamination capability.

Print shops are also using the DLF to offload short runs from larger, more expensive equipment or to add the capability to produce labels in-house—allowing for faster turnaround, better quality control, and more profitability on lower-volume label runs.

Afinia DLF-220L / DLF-350L Digital Label Finisher

Input / Output Maximum Roll Diameter: 9.84″ (250 mm)

Minimum Media Width: 3.94″ (100 mm)

Maximum Media Width: 8.86″ (225 mm)

Maximum Cutting Width: 7.87″ (200 mm) / 13″ (330 mm)

Minimum / Maximum Label Length: 11.8″ (300 mm)

Minimum Slitting Width: 0.75″ (19 mm)

Number of Slitting Blades: Up to 8

Dimensions: (W x H x L) 35.43″ x 25.60″ x 51.18″ (90 cm x 65 cm x 130 cm)

Weight (Estimated): 440 lb. (200 kg)

Roll Core Size: 3″ (76 mm)

Maximum Media Thickness: 10 mil (0.25 mm)

Maximum Cut Speed: 24 in/sec in all directions (600 mm/s)

Warranty: 1-Year parts and labor. Usage limitations may apply.

Plotter Specifications

Data Interface: USB 2.0

Linear Cut Speed: Dependent on the graphic. 2 squares across 3.15″ x 3.15″ (80 x 80 mm) = 34 labels per minute.

Programmable Cutting Force: 20 gf – 300 gf in 31 steps (Max 300 gf)

Test Cut Function: Yes.

Cut to Registration: Single point registration black mark 0.16″ (4 mm) square.

Cut Ability: Both printed and unprinted media.

Interface & Software: DLF-220 Software (Windows OS) cutter management tool. Plug-ins for CorelDraw and Adobe Illustrator.

Power Requirements: 100-240 VAC, 240 watts.

Afinia DLF-220L / DLF-350L Digital Label Finisher